Rice bran oil extraction machinery is a key equipment in the production process of rice bran oil. They work together to efficiently extract rice bran oil from rice bran. The following is a detailed introduction to rice bran oil extraction machinery:

1. Pretreatment equipment

Grain bran separator: used to remove impurities such as broken rice and rice husks mixed in rice bran, improve the purity of rice bran, facilitate the extraction of rice bran oil, and avoid equipment wear.

Modulation pot: adjust the temperature and moisture of rice bran to make it reach a good state before expansion, preparing for the subsequent puffing process.

Extruder: By spraying high-pressure steam and high-temperature water, the temperature and humidity in the extruder are increased, and the powdered rice bran is subjected to high pressure, friction, and explosion processes to change its morphology and aggregate into a porous, air-permeable columnar structure. After puffing, the cell tissue of rice bran is destroyed, and the internal pores are larger, which is conducive to leaching.

Countercurrent dryer: Dry the processed rice bran to remove excess moisture, so that the dried rice bran is more conducive to storage and subsequent leaching process.

2. Extraction equipment

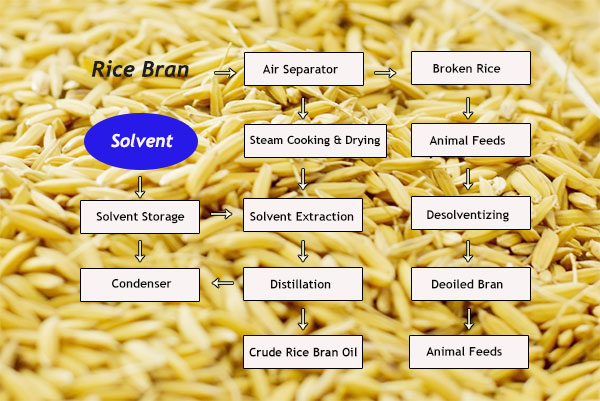

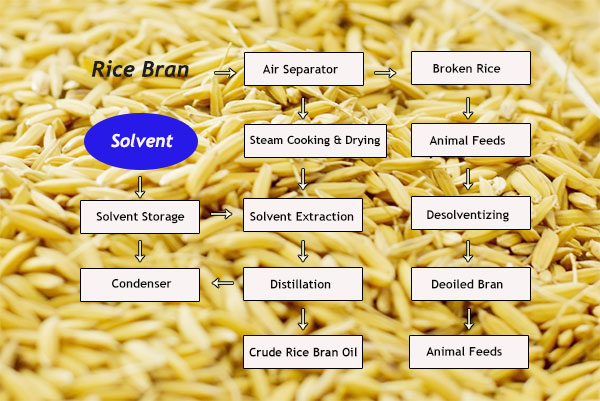

Extractor: Use solvent (such as n-hexane) to spray and soak rice bran cake to extract the oil in the cake to obtain mixed oil and wet rice bran cake.

Evaporation tower: The wet cake enters the evaporation tower for desolventizing and drying, and the solvent is removed by heating and evaporation to obtain a dry cake that meets the solvent residue standard.

Mixed oil evaporation system: The mixed oil enters the system, and the crude oil and solvent are separated by evaporation and stripping to obtain rice bran crude oil.

Mixed oil condensation recovery system: The solvent is recovered after cooling for recycling.

3. Refining equipment

Degumming equipment: Remove phospholipids and other colloidal substances in rice bran oil by physical or chemical methods.

Deacidification equipment: Use alkali neutralization method to remove free fatty acids in rice bran oil to improve the stability and quality of the oil.

Decolorization equipment: Use adsorbents (such as activated white clay) to remove pigments in rice bran oil to make the oil color clearer and more transparent.

Deodorization equipment: steam distillation is used to remove odor substances such as aldehydes and ketones from rice bran oil under high temperature and high vacuum conditions.

4. Other auxiliary equipment

Cleaning equipment: Before oil extraction, the rice bran is cleaned to remove dust and impurities on the surface.

Drying equipment: In addition to the dryer in the pretreatment stage, other drying equipment may be required to further control the moisture content of rice bran.

Filtering equipment: During or after the refining process, filter equipment such as filter screens or filter paper are used to remove impurities and solid particles from rice bran oil.

Residue processing equipment: After extracting oil from rice bran, the remaining residue is called rice bran residue. In order to effectively utilize these residues, residue processing equipment such as rice bran residue dryers and rice bran residue pellet machines can be considered to convert them into forms that can be used for feed, biomass fuel or other products.

1. Improve oil yield and oil quality

Improve oil yield: The puffing and leaching process in rice bran oil extraction machinery can effectively increase the oil yield of rice bran oil. The puffing treatment makes the rice bran form a porous and air-permeable columnar structure, which significantly increases the penetration area and speed of the solvent, thus improving the leaching efficiency. According to data, compared with unexpanded rice bran, the oil yield can be increased by 25% to 35%.

Maintain high quality: The puffing and leaching process can not only increase the oil yield, but also retain the natural active ingredients in rice bran oil, such as oryzanol, natural vitamin E, etc., making rice bran oil have better nutritional value and health benefits. In addition, by passivating lipase, the risk of rancidity of oil during storage is reduced, the shelf life of rice bran is extended, and the acid value of the extracted crude oil is reduced, significantly improving the quality of the oil.

2. Improve production efficiency

High degree of mechanization: The production process of rice bran oil extraction machinery is highly mechanized, and most of the process steps can be completed by mechanical equipment, thereby reducing manual labor intensity and improving production efficiency.

Continuous and large-scale production: The rice bran oil extraction machinery is reasonably designed to achieve continuous and large-scale production, further improving production efficiency. This helps oil plants quickly process large amounts of raw materials, adapt to market demand, and achieve economies of scale.

3. Energy saving and environmental protection

Energy saving: Rice bran oil extraction machinery can save energy during the production process. For example, by optimizing the amount of steam and circulating water, the energy consumption of the production line is reduced.

Reduce pollution: The waste gas generated during the puffing and leaching process can meet emission standards after treatment, reducing environmental pollution. This is in line with the environmental protection requirements of modern industrial production.

4. Strong adaptability

Rice bran oil extraction machinery has strong adaptability to raw materials and can handle rice bran raw materials with different oil contents. Whether it is rice bran with low oil content or rice bran with high oil content, efficient oil extraction can be achieved by adjusting process parameters.

5. Improve economic benefits

Since rice bran oil extraction machinery has the advantages of high oil rate, high production efficiency, energy saving and environmental protection, it can reduce production costs and improve economic benefits. In addition, rice bran oil, as a nutritious and healthy edible oil, has a large market demand. The use of efficient extraction machinery to produce rice bran oil can meet market demand and bring greater economic benefits to enterprises.

1. Small-scale production workshops

Scope of application: Small-scale rice bran oil production workshops usually serve the local market or small-scale distribution market.

Machinery and equipment: Such production workshops usually use small screw presses or hydraulic presses, equipped with basic pretreatment and filtration equipment.

Features: Simple operation, low investment cost, small footprint, suitable for emerging enterprises or individual operators to carry out rice bran oil production.

2. Medium-sized production enterprises

Scope of application: Medium-sized rice bran oil production enterprises usually face the regional market or serve as raw material suppliers for other food production enterprises.

Machinery and equipment: These enterprises are usually equipped with medium-sized screw presses, filtration equipment and some refining equipment, which can ensure the oil extraction rate while maintaining high product quality.

Features: Large-scale production, able to achieve a certain degree of automation, suitable for enterprises with stable supply to the regional market.

3. Large-scale industrial production

Scope of application: Large-scale industrial production enterprises usually face the national market or export market, and produce a large amount of rice bran oil for food, cosmetics, medicine and industrial fields.

Machinery and equipment: These enterprises usually use fully automated production lines, including efficient screw presses, a full set of refining equipment (degumming, deacidification, decolorization, deodorization), filtering equipment and automatic packaging lines.

Features: Large-scale continuous production, high degree of automation, able to meet the production needs of high quality and large quantities, suitable for enterprises with long-term market strategies.

4. Food processing enterprises

Scope of application: Some food processing enterprises may use rice bran oil as raw material for the production of food additives, condiments and other products.

Machinery and equipment: These enterprises may not directly extract rice bran oil, but purchase it from specialized rice bran oil production enterprises. However, for qualified enterprises, they may also equip themselves with small and medium-sized rice bran oil extraction equipment to achieve full-chain control of the production process.

Features: The quality requirements for rice bran oil are high, and they usually pay more attention to the purity and nutrient retention of rice bran oil.

5. Pharmaceutical and cosmetics industry

Scope of application: Rice bran oil is used in the pharmaceutical and cosmetics industry to manufacture medicines, skin care products, hair care products, etc.

Machinery and Equipment: Companies in these industries have very high requirements for the purity of rice bran oil, and usually purchase highly refined rice bran oil or refine crude oil themselves.

Features: The product quality requirements are strict, and the content of impurities in the oil needs to be strictly controlled to ensure the safety and effectiveness of the final product.

6. Feed and Industrial Applications

Scope of Application: Rice bran oil is also used in the production of animal feed, lubricants, soaps, chemical products and other industrial applications.

Machinery and Equipment: Such applications have relatively low requirements for the refining of rice bran oil, but require equipment that can extract oil efficiently and at low cost.

Features: Production cost control is the key, and the equipment needs to be highly efficient and durable to meet the needs of large-scale industrial applications.

.png)