Palm kernel oil extraction machinery is a vital part of the palm oil processing industry. It is mainly responsible for extracting high-quality palm kernel oil from palm kernels.

Palm kernel oil extraction machinery is a series of complex and sophisticated equipment combinations. They use physical or chemical methods to extract the oil from palm kernels efficiently and stably. These equipment usually include crushers, centrifuges, presses, distillation towers, reactors, etc. Each link is crucial and together constitutes a complete extraction process.

Main equipment types and functions

Crusher: As the first step in the extraction process, the crusher is responsible for breaking the palm kernels into small pieces or powder for better processing by subsequent equipment. Crusher usually uses high-speed rotating blades or hammers to ensure that the kernels are evenly broken.

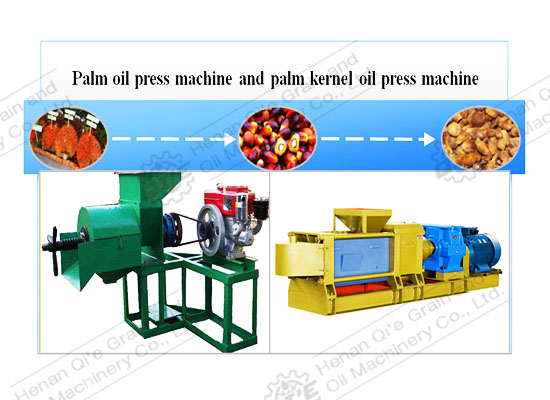

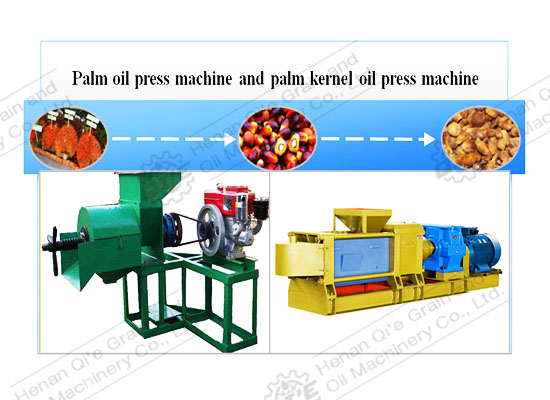

Press: The press is one of the core equipment for extracting palm kernel oil. It uses mechanical pressure to squeeze out the oil from the crushed palm kernels. Common presses are screw presses and hydraulic presses. The screw press squeezes the kernels into a cake shape and separates the oil through the rotation and advancement of the screw shaft; while the hydraulic press directly squeezes the kernels through the pressure generated by the high-pressure oil pump.

Centrifuge: The centrifuge is mainly used to separate the oil, water and solid residue produced during the pressing process. Under high-speed rotation, substances of different densities will be separated to different positions, thereby achieving oil purification. The centrifuge can not only improve the purity of palm kernel oil, but also effectively reduce the difficulty of subsequent processing.

Distillation tower: For palm kernel oil that needs further purification, the distillation tower is an indispensable equipment. Through heating and evaporation, the distillation tower can remove impurities and bad odors in the oil and improve the quality of the oil. At the same time, the distillation tower can also separate oil components with different boiling points to obtain oil products with various uses.

Reactor: In some cases, in order to improve the yield or quality of palm kernel oil, a chemical reactor is also required for special treatment. Chemical reactions such as acid-base neutralization and ester exchange can be carried out in the reactor to change the chemical composition and physical properties of the oil.

When choosing palm kernel oil extraction machinery, multiple factors need to be considered to ensure the applicability and efficiency of the equipment. First, the appropriate equipment model and quantity should be selected according to the production scale. Large-scale production requires the selection of equipment with large processing capacity and high efficiency; while small-scale production can choose a more flexible and economical equipment combination.

Secondly, attention should be paid to the quality and stability of the equipment. High-quality equipment can not only improve production efficiency, but also reduce failure and maintenance costs. Therefore, when choosing equipment, suppliers with good reputation and after-sales service should be selected.

In addition, the energy consumption and environmental performance of the equipment should also be considered. With the improvement of environmental awareness, more and more companies have begun to pay attention to the green production capacity of equipment. Therefore, when choosing equipment, attention should be paid to whether its energy consumption indicators and emission standards meet national and local regulations.

Palm kernel oil extraction machinery is one of the key equipment in the palm oil processing industry. They extract oil from palm kernels efficiently through a series of complex processing processes. When selecting and using these equipment, it is necessary to comprehensively consider multiple factors such as production scale, equipment quality, stability, energy consumption and environmental performance to ensure the efficiency and sustainability of production. With the continuous development and progress of science and technology, it is believed that palm kernel oil extraction machinery will become more intelligent, efficient and environmentally friendly, bringing broader development prospects to the palm oil processing industry.

.png)