Cottonseed oil extraction machinery is a device specially used to extract oil from cottonseed. These devices usually include pretreatment equipment, pressing equipment, refining equipment and other components. The following is a detailed introduction to cottonseed oil extraction machinery:

1. Pretreatment equipment

Before cottonseed oil is extracted, cottonseeds need to be pretreated to remove impurities and adjust their physical properties to make them more suitable for subsequent pressing and refining processes. Pretreatment equipment may include:

Cleaning equipment: used to remove impurities in cottonseeds, such as soil, stones, cotton fibers, etc.

Crushing equipment: crush cottonseeds into smaller particles to increase their surface area for easy oil extraction.

Softening equipment: through heating and moistening treatment, the hardness and brittleness of cottonseeds are reduced and the oil yield is increased.

2. Pressing equipment

Pressing equipment is a key part of cottonseed oil extraction. Oil is separated from cottonseeds by physical pressing. Common pressing equipment includes screw oil presses and hydraulic oil presses. Their working principles are slightly different, but they can effectively extract oil.

Screw oil press: The rotation and propulsion of the screw shaft are used to send cotton seeds into the pressing chamber, and the oil is squeezed out through high pressure and shear force. The screw oil press has the advantages of simple structure, easy operation, and high oil yield.

Hydraulic oil press: The oil in the cotton seeds is squeezed out by the high pressure generated by the hydraulic system. The hydraulic oil press is suitable for squeezing a variety of oils, and the squeezed oil is of high quality.

3. Refining equipment

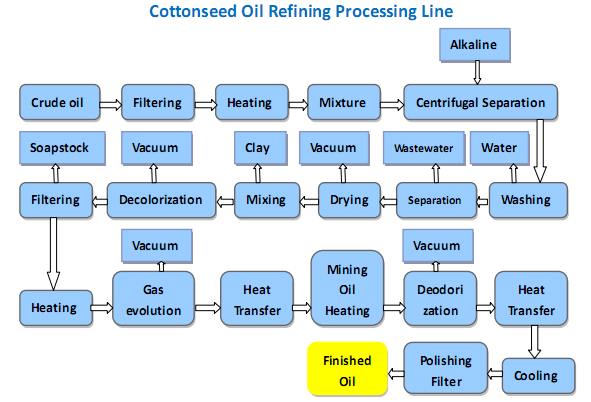

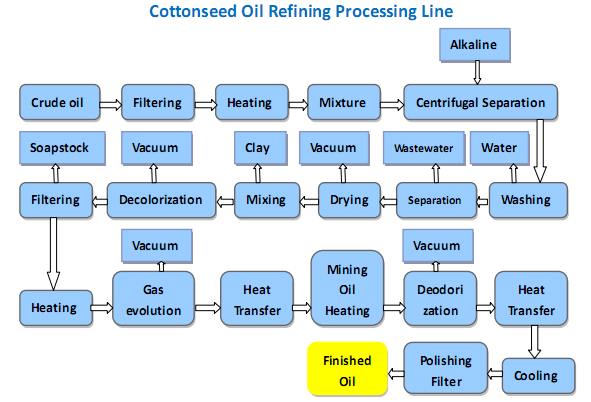

The squeezed cottonseed oil is called crude oil, which contains more impurities and undesirable components, such as phospholipids, free fatty acids, pigments, colloids, etc. In order to improve the quality and stability of cottonseed oil, it needs to be refined. Refining equipment usually includes process units such as deacidification, degumming, decolorization, and deodorization, and impurities and undesirable components are removed by physical, chemical or physicochemical methods.

Deacidification equipment: Use the principle of acid-base neutralization to remove acidic substances such as free fatty acids in cottonseed oil.

Degumming equipment: Remove colloid substances such as phospholipids in cottonseed oil through heating and hydration.

Decolorization equipment: Use adsorbents (such as activated carbon, clay, etc.) to remove pigments and impurities in cottonseed oil to make its color clearer and more transparent.

Deodorization equipment: Remove odors and volatile substances in cottonseed oil through high temperature, vacuum and steam distillation.

4. Other auxiliary equipment

In addition to the above main equipment, some auxiliary equipment is also required in the cottonseed oil extraction process, such as conveying equipment, storage equipment, heating equipment, etc. These equipment play an important role in the cottonseed oil extraction process and ensure the smooth progress of the entire production process.

1. Efficient oil extraction capacity

High oil yield: Modern cottonseed oil extraction machinery, such as screw oil presses and hydraulic oil presses, can extract the oil from cottonseed to the maximum extent. Especially for large cottonseed oil processing plants, the process of pre-pressing and then leaching can be used to pre-press most of the oil from cottonseed, and then the pre-pressed cake can be crushed and leached to further increase the oil yield.

Quick processing: The mechanized extraction process can quickly process a large amount of cottonseed, shorten the production cycle, and improve production efficiency.

2. Technological advancement and adaptability

Low-temperature processing: The extraction method for cottonseed oil is carried out under low temperature conditions, which can largely avoid protein denaturation and destruction, and ensure the nutritional value of cottonseed protein products.

Combination of multiple processes: The traditional shelling-pressing method for oil production has been replaced by the more advanced shelling-pre-pressing, leaching or shelling-rolling (expansion molding)-direct leaching oil production process. The combined use of these processes not only improves the oil yield, but also optimizes the quality of cake, making it more suitable as feed.

3. Easy operation and maintenance

High degree of automation: Modern cottonseed oil extraction machinery mostly adopts automated control systems, which are easy to operate, reduce dependence on manual labor, and also reduce errors caused by manual operation.

Easy maintenance: The equipment is reasonably designed and compact in structure, which is convenient for daily maintenance and upkeep. For example, the design of the screw oil press focuses on easy maintenance, which is convenient for users to clean and repair.

4. Environmental protection and energy saving

Low energy consumption: Advanced cottonseed oil extraction machinery is more efficient in energy utilization and can reduce energy consumption compared with traditional processes.

Environmental treatment: The solvent used in the leaching oil production process can be effectively recovered through the recovery system, reducing environmental pollution. At the same time, the wastewater and waste gas generated during the refining process can also be treated through environmental protection facilities to meet emission standards.

5. Product quality improvement

Effective removal of harmful substances: Refining equipment can remove harmful substances such as free fatty acids, phospholipids, pigments, cottonphenol, etc. in cottonseed oil, and improve the quality and safety of oil products.

1. Crop processing field

Cottonseed processing: Cottonseed oil extraction machinery is specially designed for processing cottonseed and can efficiently extract oil from cottonseed. These equipment usually include pretreatment, pressing, refining and other links to ensure the quality and yield of cottonseed oil.

2. Oil processing industry

Oil extraction: Cottonseed oil extraction machinery is not limited to cottonseed, but can also process other oil crops, such as sesame, peanuts, soybeans, etc., and extract oil from these oil crops through similar process flow.

Oil refining: The extracted crude oil often needs to be refined to remove impurities and undesirable components to improve the quality and stability of the oil. The refining equipment in cottonseed oil extraction machinery can complete this task, making the oil more suitable for people's daily consumption and industrial use.

3. Industrial application field

Lubricant production: Cottonseed oil can also be used as a raw material for lubricants after proper treatment. Cottonseed oil extraction machinery can provide high-quality oil raw materials for lubricant production.

Plant protein extraction: In the process of cottonseed processing, in addition to extracting oil, plant protein can also be further extracted. These plant proteins have a wide range of application values, such as feed, food additives, etc. The relevant equipment in cottonseed oil extraction machinery can support this extraction process.

4. Environmental protection and resource utilization

Waste treatment: Waste generated during cottonseed processing, such as cake residues, seed kernels, etc., can be used as feed for poultry and livestock through proper treatment, or as other industrial raw materials. Cottonseed oil extraction machinery plays an important role in reducing waste generation and improving resource utilization.

Environmental protection treatment: Modern cottonseed oil extraction machinery focuses on environmental protection treatment, which can reduce the emission of pollutants such as wastewater and waste gas, and reuse resources such as solvents through recycling systems to reduce the impact on the environment.

5. Applicable scale

Small farmers: For small farmers or family workshops, small cottonseed oil extraction machinery can be selected for self-production and sales or small-scale processing.

Large factories: For large oil processing plants or agricultural cooperatives, large, efficient and automated cottonseed oil extraction machinery needs to be selected to meet the needs of large-scale production.

.png)